There are many different types of printing methods that are used to make stickers. Also, it depends on the type of sticker stock and artwork that is needed to determine which method we print stickers that is most cost effective as well as producing excellent quality prints.

We do not have a one type of sticker fits all approach and look for many different ways to produce stickers using different machines therefore using different methods.

Here are the 4 types of printing machines we use at MyStickers.

![]() Off-Set Printing

Off-Set Printing

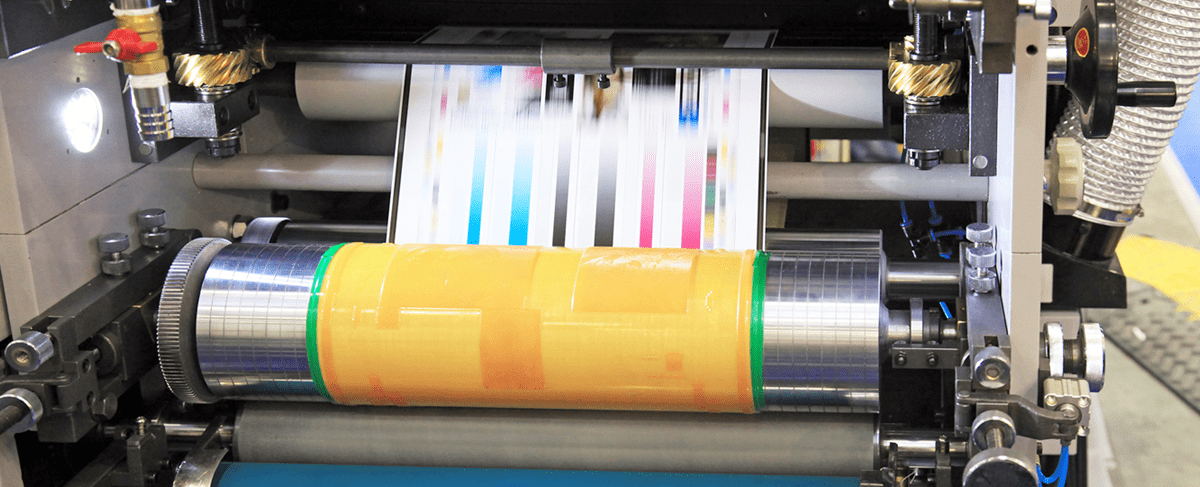

![]() Rotary Printing

Rotary Printing

![]() Press

Press

![]() Digital Printing

Digital Printing

![]() Screen Printing

Screen Printing

Offset Printing is a technology that uses metal plates for each of the CMYK colours and then used to transfer that image onto a rubber “blanket” which then the image is rolled onto the sheet of Paper or Vinyl material. Because the ink is not directly transferred onto the substrate you get the term OFFSET.

This choice is usually used for larger quantities and produces accurate reproduction which are crisp and profession looking.

Digitally printing is usually used when smaller quantities are needed. The production time is much quicker than Offset and setup costs are much cheaper however, when printing very small texts and very fine prints, this is where they lack. However, they do have many advantages for example, when variable data is needed eg unique codes, address or name which offset cannot do.